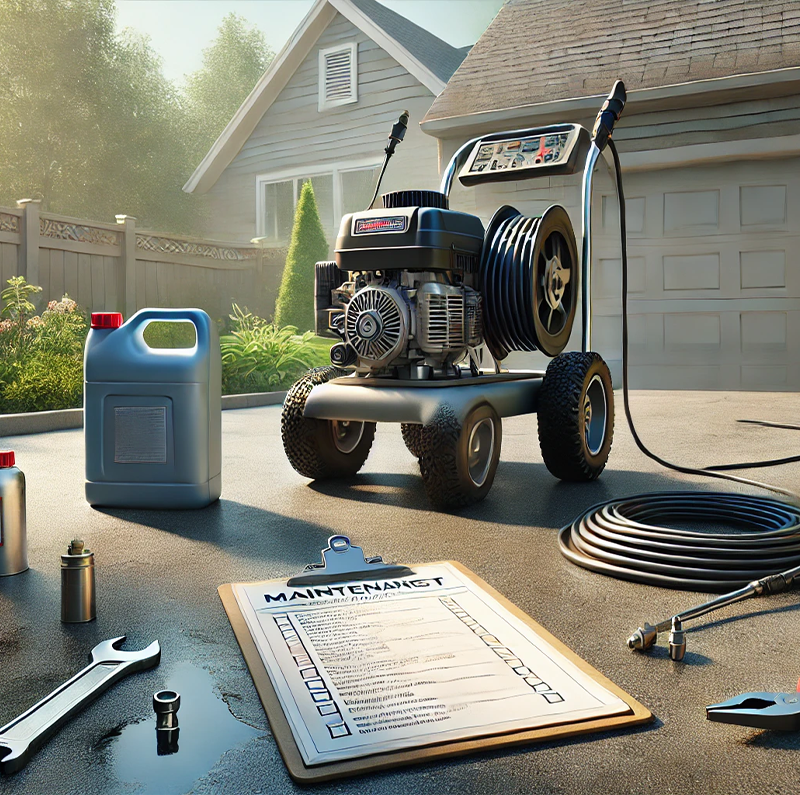

Pressure Washer Maintenance Checklist: Keep Your Equipment Job-Ready

Why Pressure Washer Maintenance Matters

For contractors and professionals in the pressure washing industry, your equipment is your livelihood. Whether you’re handling residential driveways or commercial buildings, a properly maintained pressure washer ensures safety, efficiency, and consistent results.

Neglecting maintenance can lead to poor performance, unexpected downtime, or costly repairs—especially when working with harsh chemicals like sodium hypochlorite or industrial degreasers. In this post, we break down a complete maintenance checklist that will keep your machine in top condition before, during, and after every job.

Pressure Washer Maintenance: Before and After Each Job

1. Inspect the Hoses and Fittings

What To Do:

- Check for leaks, kinks, abrasions, or cracks in pressure and chemical hoses

- Ensure all fittings are secure and not corroded

- Inspect quick connects and replace damaged O-rings

2. Examine the Spray Gun and Nozzles

What To Do:

- Make sure the spray trigger operates smoothly

- Check nozzles for clogs or wear

- Clean nozzles with a specialized nozzle cleaning tool or needle

Need Replacements? Browse Professional-Grade Nozzles

3. Check for Fuel or Oil Leaks

What To Do:

- Inspect the engine and pump area for oil drips or gas smells

- Tighten any loose fittings and clean spills immediately

4. Flush the System with Clean Water

What To Do:

- Run clean water through the unit to remove residual chemicals

- Prevents cross-contamination and prolongs pump life

5. Empty and Rinse the Chemical Tank (if applicable)

What To Do:

- Drain any leftover cleaning solution

- Rinse with water or a neutralizing agent

- This prevents chemical buildup or damage from aggressive cleaners

Need Safe Tools? Explore Safe Chemical Handling Tools

Weekly Maintenance Tasks

6. Change or Check the Engine Oil (Gas-Powered Units)

What To Do:

- Most units require an oil change after the first 5 hours, then every 50 hours

- Use manufacturer-recommended oil types

- Clean or replace the oil filter if applicable

7. Clean the Water Inlet Filter

What To Do:

- Detach the inlet screen and rinse off dirt, mineral deposits, and debris

- A clogged filter can reduce water flow and damage the pump

8. Check Pump Oil (if applicable)

What To Do:

- Inspect the sight glass or dipstick for proper oil level

- Look for milky oil, which could indicate water contamination

8. Check Pump Oil (if applicable)

What To Do:

- Inspect the sight glass or dipstick for proper oil level

- Look for milky oil, which could indicate water contamination

Monthly Pressure Washer Maintenance

9. Inspect the Spark Plug (Gas-Powered Models)

What To Do:

- Remove and inspect for carbon buildup or wear

- Clean with a wire brush or replace if needed

- Improves ignition performance and fuel efficiency

10. Inspect All Belts and Fasteners

What To Do:

- Check for loose bolts, cracked belts, or worn pulleys

- Tighten hardware and replace worn parts to prevent mid-job breakdowns

11. Descale the Pump (if operating in hard water areas)

What To Do:

- Use a pump descaler monthly to remove lime scale buildup

- Ensures consistent pressure output and pump longevity

Seasonal or Long-Term Storage Maintenance

12. Add Pump Saver or Antifreeze (Cold Weather Protection)

What To Do:

- Prevents freezing damage and corrosion inside the pump

- Ideal for off-season storage or freezing climates

13. Drain All Fluids Before Long-Term Storage

What To Do:

- Empty the fuel tank or add fuel stabilizer

- Drain water and cleaning solutions from all tanks, hoses, and the pump

14. Store in a Dry, Sheltered Environment

What To Do:

- Keep your pressure washer in a climate-controlled or covered space

- Protects from moisture, rodents, and UV exposure

Common Pressure Washer Maintenance Mistakes to Avoid

Avoid these frequent errors to protect your maintenance:

- Skipping flushes after using harsh chemicals like sodium hypochlorite

- Forgetting to inspect fittings and hoses until they leak

- Leaving gas in the tank during long periods of inactivity

- Using non-OEM or incompatible replacement parts

- Overlooking minor oil leaks or worn O-rings

Frequently Asked Questions (FAQs)

Q1: How often should I change my pressure washer oil? A: After the first 5 hours of use, then every 50 hours or at least once per season.

Q2: Can I use bleach or sodium hypochlorite in my pressure washer? A: Yes, if your equipment is rated for it. Always flush the system afterward and use chemical-safe hoses and tanks.

Q3: What’s the best way to prevent pump damage? A: Flush with water after each use, use pump saver fluid, and never run the pump dry.

Conclusion: Keep Your Pressure Washer Running Like New

A well-maintained pressure washer saves you time, money, and headaches. By following this routine maintenance checklist, you’ll protect your investment and deliver high-quality results every time.

LNI Equipment is your trusted source for pressure washers, replacement parts, hoses, nozzles, chemicals, and accessories. Whether you're starting your business or scaling up your fleet, we’ve got the gear you can rely on.

Ready to upgrade your pressure washing setup?

Shop Now: Shop Now at LNI Equipment